First Year

Second Year

Third and Fourth Year

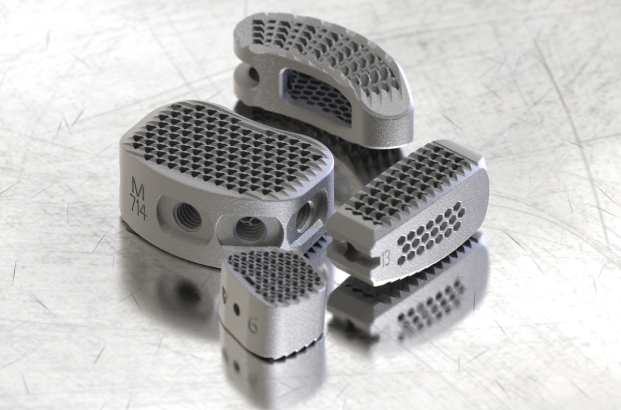

As a machinist, you will work in production halls. In order to ensure that machine noise, metal dust, and shavings don’t take the fun out of your work, you are required to wear protective clothing such as safety goggles, work gloves, and hearing protection depending on the respective task.

In this apprenticeship, accuracy and precision are important – not only so that the components fit together afterwards but also for your own safety.

Following precise consultation, you will work independently and intently on our machines. You should be able to stand for long periods.

The daily routine of a cutting machine operator includes cleaning and maintaining the machines.

Exciting challenge

Creativity and innovation at its best

Future-proof industry

Personal development

Vacation and Christmas allowance

Various free cold drinks and coffee

Fuel card or

MAXX ticket

Digital

report booklet