With its many years of industry experience as an excellent development partner CPM Precision can help you develop new, high-performance medical products. We support you from the concept to the finished product.

With your product portfolio in mind, we work with you to identify opportunities to develop innovations or optimize manufacturing and design processes. As an expert partner for medical technology, we show you how to realize innovative medical products that will give you a competitive edge.

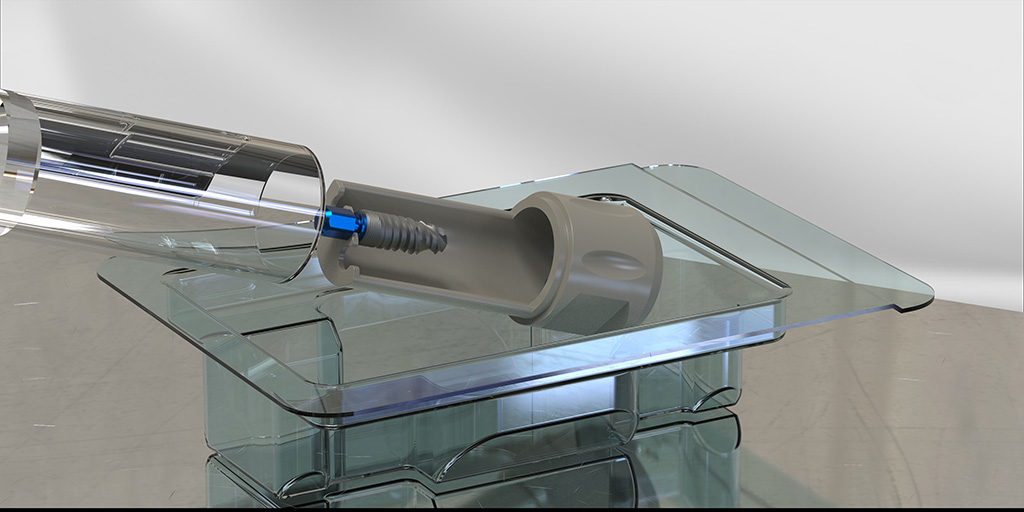

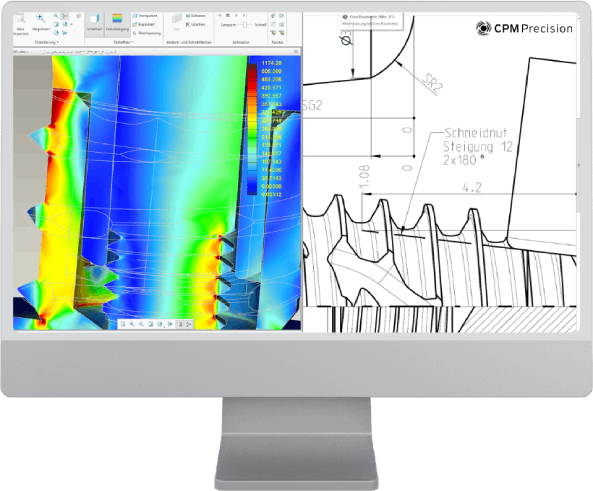

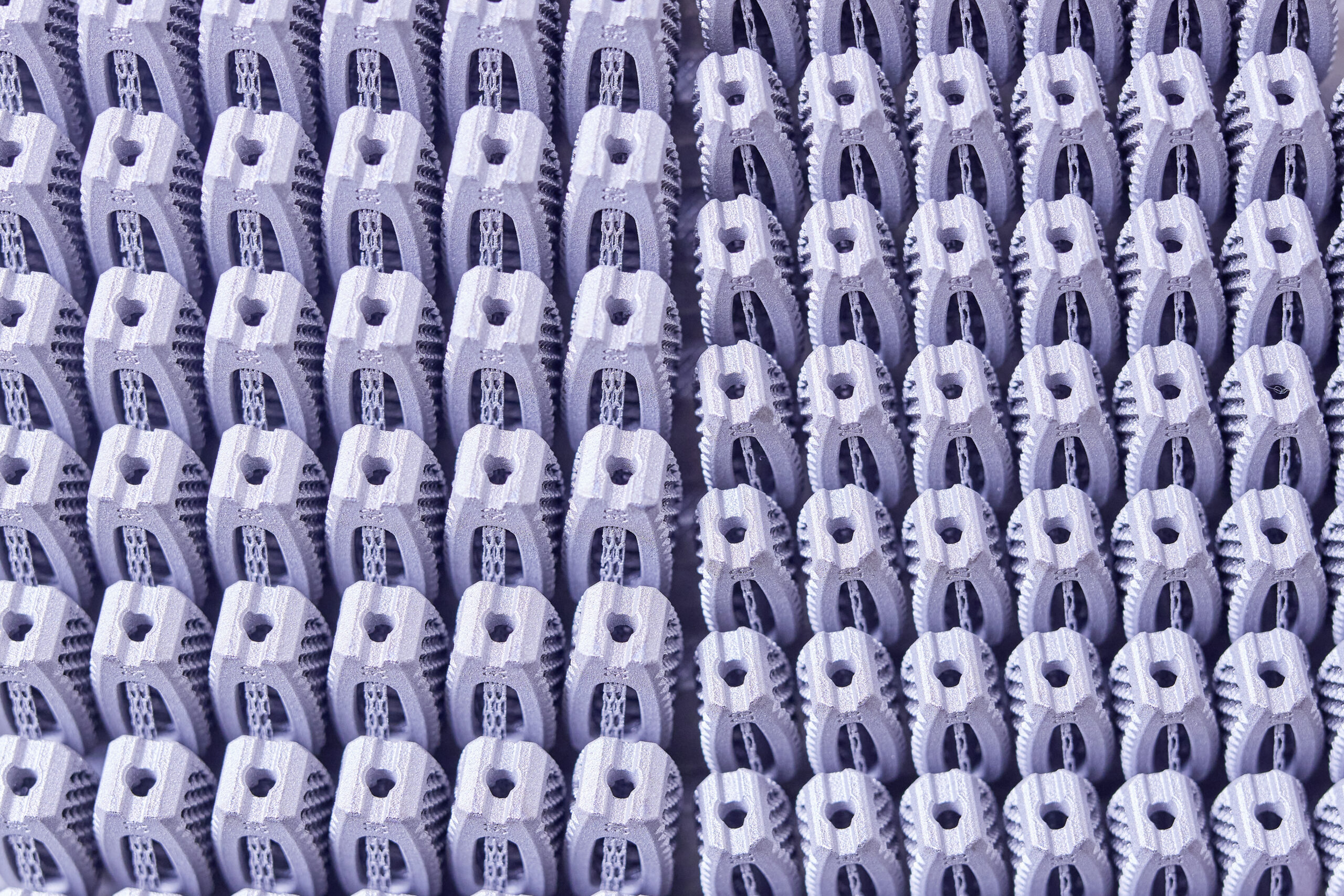

We would be happy to check whether additive manufacturing is possible for your application – even for smaller quantities or with a lower budget. What’s more: On request, we can take over the rendering for product catalogs or show worst-case products for approval tests as part of FEM calculations. We support the production of prototypes and create all required initial sample test reports. We document all results of our development work in accordance with ISO 13485.

Initial consultation

The first step is to listen: What project do you have planned? What should your product do? What innovations on top of your portfolio are conceivable? Do you already have a specific vision or initial ideas? Or do you already have a completed specification sheet? No matter what briefing you have for us: Our experts can use these foundations to develop new medical technology products and build on them. We always have an open ear.

Design

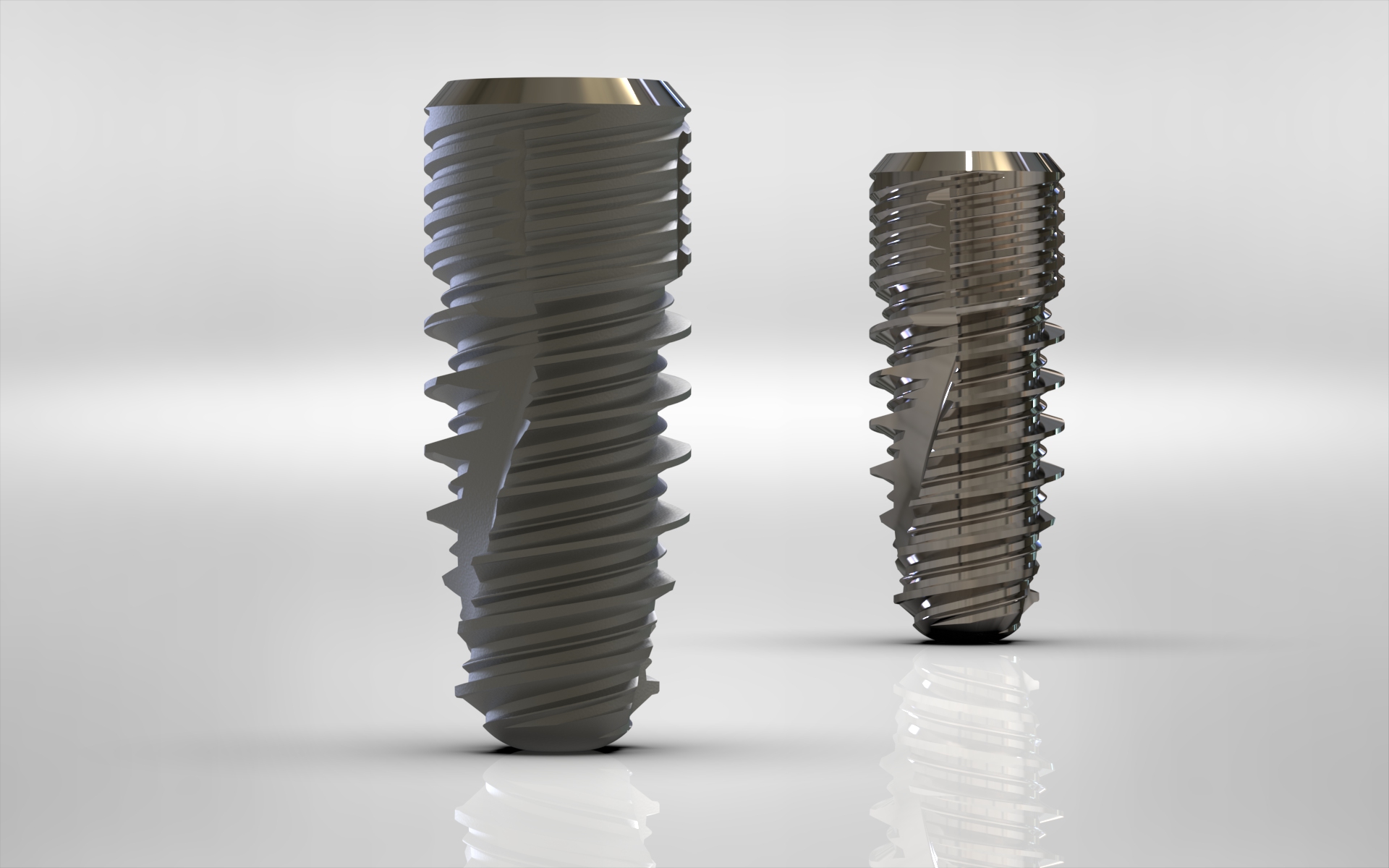

The briefing is followed by the design: Based on all specifications, we define the product attributes and functions as the basis for further cooperation. On request, we develop solutions to optimally implement all requirements and create designs that can be rendered for a visual product presentation.

Prototype

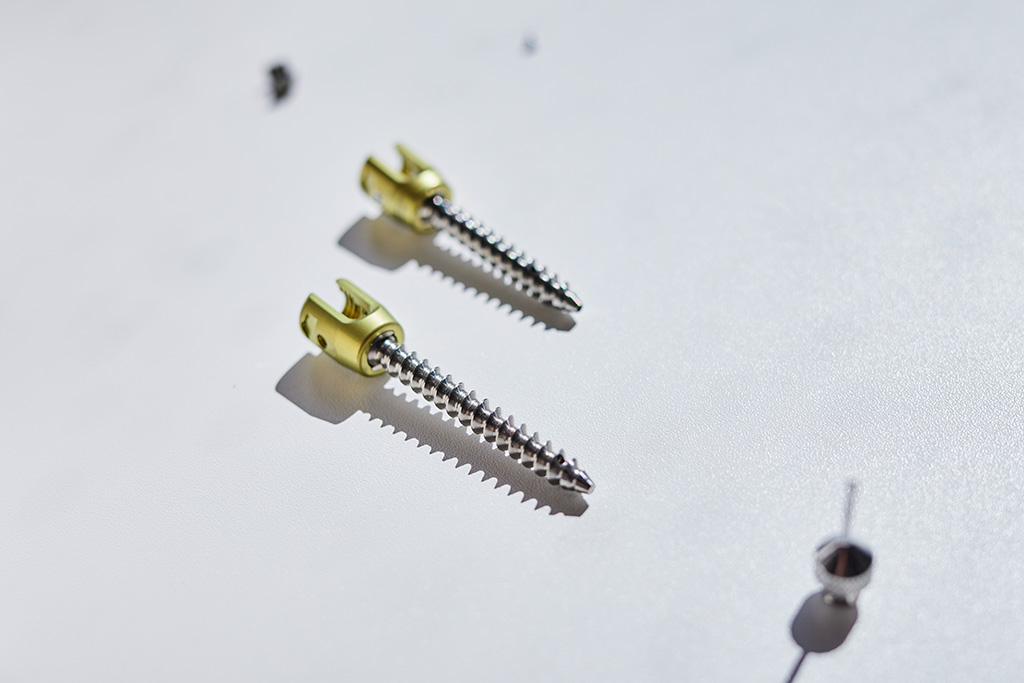

Precision right from the start: In prototype production, our customers benefit from the intensive support of a specialized designer, who closely monitors production and can make further optimizations during the process in order to achieve the best possible result. Particularly in the case of turned and milled parts, where every micrometer of precision counts, fine-tuning often means that reworking can be avoided. This greatly reduces the time to market.

Once the prototype has been created, you can choose how to proceed: Whether CPM Precision implements series production and continues the process or outsources it.

First series

The prototype as a basis: Throughout the entire process of manufacturing an initial series, we continually monitor the quality requirements and quality assurance with the utmost care in accordance with our extremely high precision standards. Finally, in the last process step, the product is subjected to a final test (initial sample test report). The control of the successful design transfer to series production is particularly important.

Would you like advice on developing your product idea? Are you planning to optimize your medical products? Send us your inquiry using our online form – we look forward to a non-binding exchange!

Schedule a free initial consultation

Consulting and development have always been among the most important services of CPM Precision. We have been developing projects and products for medical technology since 2000. We are responsible and reliable, straightforward, and always open to individual requests.

We are always well informed about what is happening in the medical technology sector and bring this expertise to our consulting services. In addition, our state-of-the-art equipment contributes to the efficient and high-quality implementation of your products.