Cleaning: Cleanliness Is a Must

Our cleaning processes set standards in efficiency and environmental compatibility. With the fully automated REK FC-500-VZ cleaning system, we achieve impressive results in cleaning, degreasing, and drying. This environmentally friendly solution is characterized by low-emission filter drying and continuous treatment of the medium. The system is not only validated but also regularly tested by external laboratories for cleanliness and purity of the parts.

For sensitive parts made of plastic or aluminum, we offer gentle ultrasonic cleaning that guarantees uncompromising cleanliness.

Quality Assurance: Tested Precision for Every Part

Our intermediate inspection experts check all finished and externally delivered parts.

This ensures that every part is cleaned and passes on to the next process line in perfect condition.

Laser Marking Individual Labeling

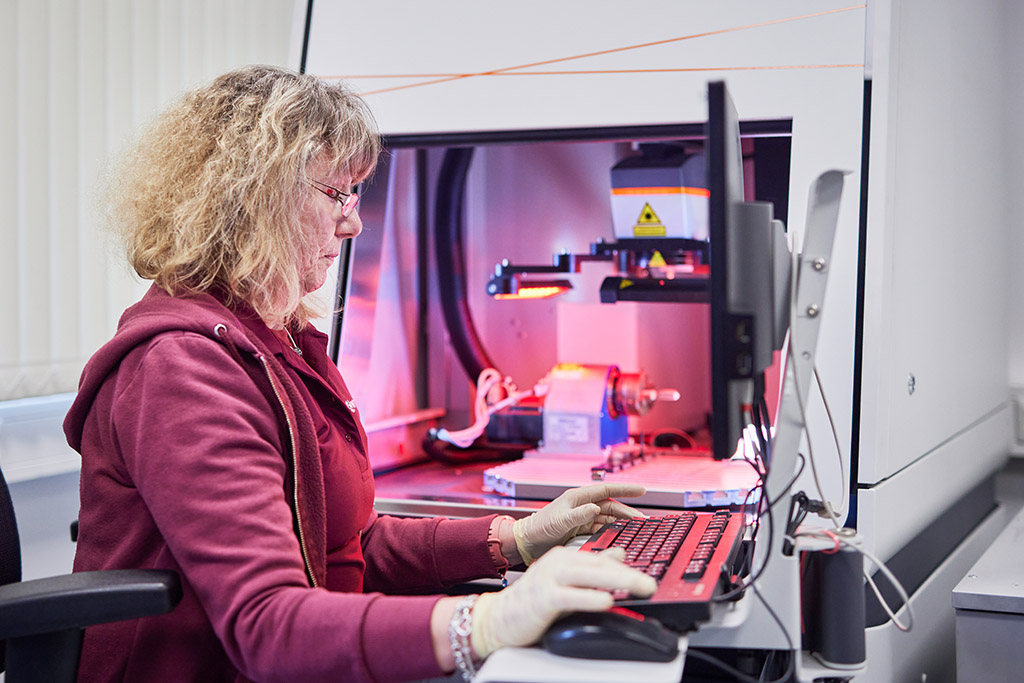

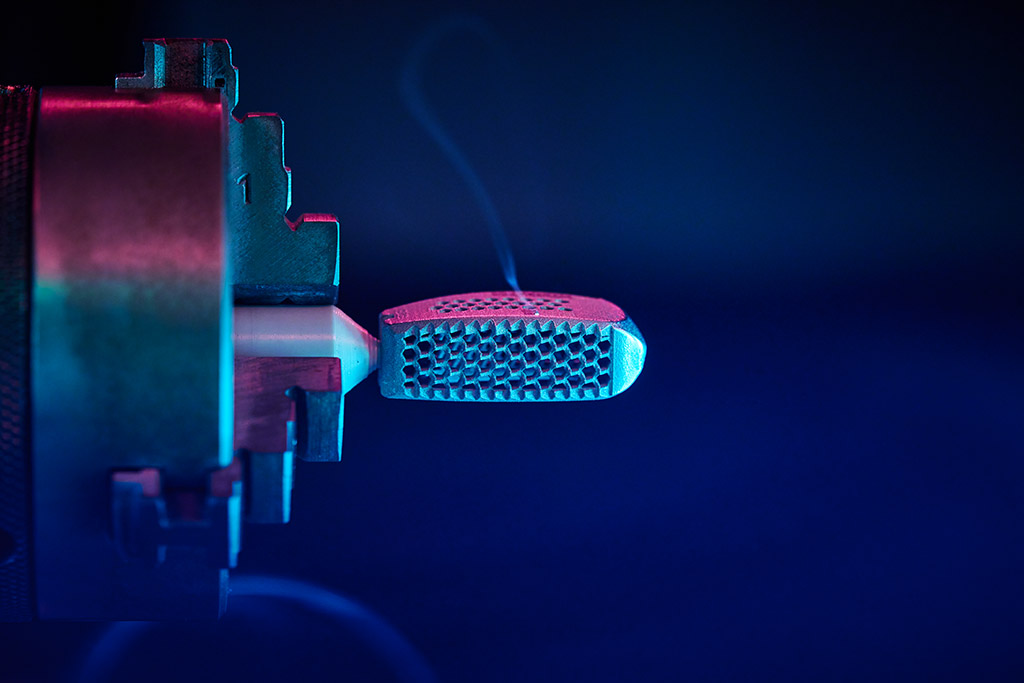

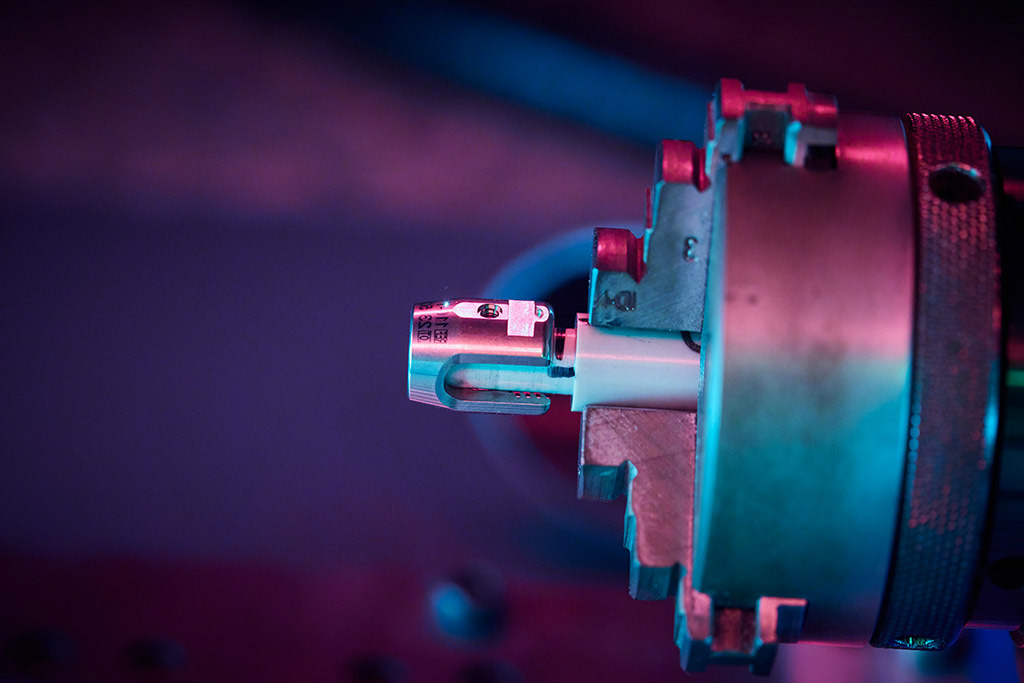

With our state-of-the-art laser device, which is equipped with integrated camera inspection, our laser specialists mark or label parts in accordance with your wishes and requirements. This device is suitable for small to large and geometrically complex parts made from various materials, including titanium, stainless steel, and aluminum.

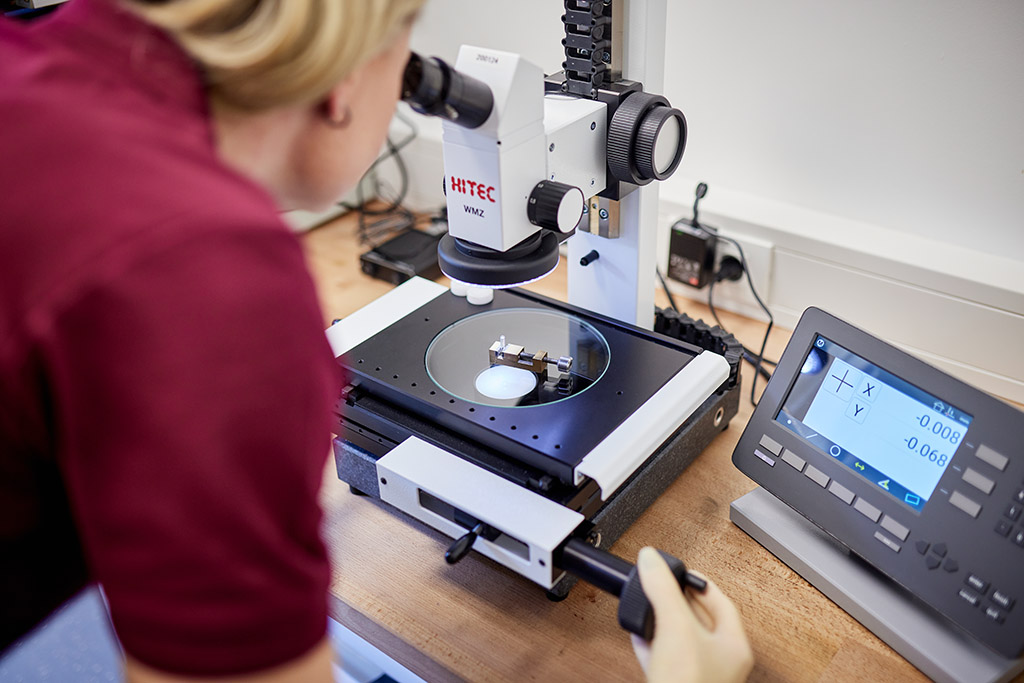

The final inspection is carried out by our experienced inspection team, who performs a 100% product inspection based on customer specifications and requirements. We use state-of-the-art testing equipment to ensure the quality of each individual part and sort out good parts and any rejects. The optical inspection is carried out on an Olympus stereo microscope, and the dimensions of the items are measured on modern digital profile projectors and measuring microscopes and digitally recorded in our system.

On request, we can also carry out a surface treatment before the final inspection. In the final inspection, each order is completed (including final quantity determination and inspection documents), carefully packed, and prepared for dispatch to our logistics center.

At CPM Precision, finishing is more than just a final step – it’s our promise to our customers that every detail counts and that every detail is right.

At CPM Precision, we are committed to excellence – also in every step of the testing and in further processing. Our state-of-the-art laser and cleaning systems ensure the highest level of quality.